- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

Mckinsey 7s Framework Of Measuring Information Technology Internal Service Quality in a Manufacturing Environment

Posted by Matthew Harvey on Feb-11-2020

Introduction

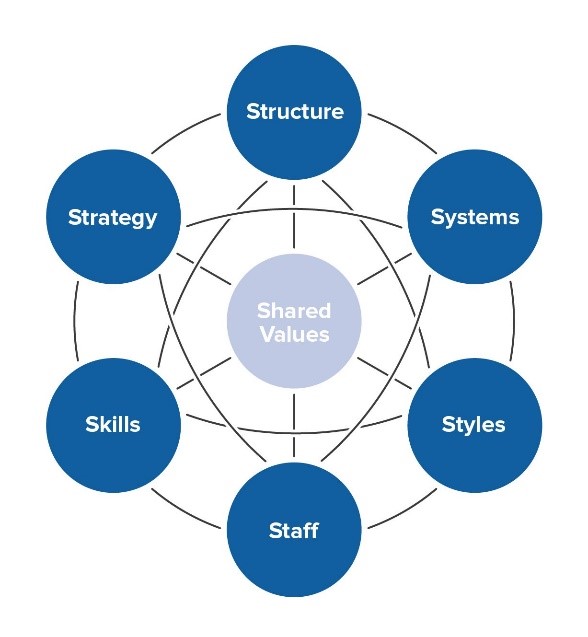

The McKinsey 7s model is a strategic tool and framework that helps managers and businesses assess their performance. The McKinsey 7s model identifies 7 key elements for an organization that need to be focused and aligned for successful change management processes as well as for regular performance enhancements.

Figure 1 McKinsey 7S Model

The 7 elements identified in the McKinsey 7s model can be categorized as being hard or soft in nature. They are identified as:

| Hard Elements | Soft Elements |

|---|---|

| Shared Values | |

| Strategy | Skills |

| Structure | Style |

| Systems | Staff |

Figure 2 Hard and Soft elements of the McKinsey 7S Model

Measuring Information Technology Internal Service Quality in a Manufacturing Environment makes use of the McKinsey 7s model to regularly enhance its performance, and implement successful change management processes. Measuring Information Technology Internal Service Quality in a Manufacturing Environment focuses on the 7 elements identified in the model to ensure that its performance levels are consistently maintained, and improved for the offerings.

1. Hard elements

The hard elements of the McKinsey 7s model comprise of strategy, structure, and systems. The hard elements of the model are easier to identify, more tangible in nature, and directly controlled and influenced by the leadership and management of the organization.

1.1. Strategy

1.1.1. Clearly defined

The strategic direction and the overall business strategy for Measuring Information Technology Internal Service Quality in a Manufacturing Environment are clearly defined and communicated to all the employees and stakeholders. This helps the organization manage performance, guide actions, and devise different tactics that are aligned with the business strategy. Moreover, the business strategy’s definition and communication also make operations for Measuring Information Technology Internal Service Quality in a Manufacturing Environment more transparent and aligns the responsibilities and actions of the company.

1.1.2. Guiding behaviour for goal attainment

The strategic direction for Measuring Information Technology Internal Service Quality in a Manufacturing Environment is also important in helping the business guide employee, staff, and stakeholder behaviour towards the attainment and achievement of goals. SMART Goals are set with short and long term deadlines in accordance with the business strategy. The business strategy helps employees decide tactics and behaviours for attaining the set goals and targets to help the business grow.

1.1.3. Competitive pressures

Measuring Information Technology Internal Service Quality in a Manufacturing Environment’s strategy also takes into consideration the competitive pressures and activities of competitors. The strategy addresses these competitive pressures through suggestive measures and actions to address competition via strategic tactics and activities that ensure sustainability to Measuring Information Technology Internal Service Quality in a Manufacturing Environment via adapting to market changes, and evolving consumer trends and demands.

1.1.4. Changing consumer demands

An important aspect of the strategy at Measuring Information Technology Internal Service Quality in a Manufacturing Environment is that it takes into constant consideration the changing consumer

trends and demands, as well as the evolving consumer market patterns and consumption behavior. This is an important

part of the strategic direction at Measuring Information Technology Internal Service Quality in a Manufacturing Environment as it allows the company to remain competitive and relevant to its target

consumer groups, as well as allows the company to identify demand gaps in the consumer market.

The company

then strategically addresses these gaps through product offerings and marketing activities which give the company

successful and leading-edge over other patterns in the market.

1.1.5. Flexibility and adaptability

The strategy at Measuring Information Technology Internal Service Quality in a Manufacturing Environment is flexible and adaptable. This is an important aspect of the strategic direction, and strategy setting at Measuring Information Technology Internal Service Quality in a Manufacturing Environment. Rigidity in strategy leads a company and a business to often become stagnant and obstructs advancement, and progression with evolving changes in the consumer markets.

With flexibility and adaptability, the Measuring Information Technology Internal Service Quality in a Manufacturing Environment is not only able to benefit from quickly reacting and responding to changing consumer patterns globally, but is also able to locally and culturally adapt its products via localization for different countries and regions. Moreover, the company is often able to proactively predict consumer market changes, and devise strategic changes accordingly to meet the market trends.

1.2. Structure

1.2.1. Organizational hierarchy

Measuring Information Technology Internal Service Quality in a Manufacturing Environment has a flatter organizational hierarchy that is supported by learning and progressive organizations. With lesser managerial levels in between and more access to the senior management and leadership, the employees feel more secure and confident and also have higher access to information. Moreover, the flatter hierarchy also allows quicker decision-making processes for Measuring Information Technology Internal Service Quality in a Manufacturing Environment and increases organizational commitment in the employees.

1.2.2. Inter-Departmental coordination

Measuring Information Technology Internal Service Quality in a Manufacturing Environment has high coordination between different departments. The company’s departments often form inter-department teams for projects and tasks that require multiple expertise. All coordination between different departments is effective and organized. Measuring Information Technology Internal Service Quality in a Manufacturing Environment has a systematic process for initiating and monitoring coordination between departments to ensure smooth work operations and processes – and goal attainment.

1.2.3. Internal team dynamics [department specific]

Measuring Information Technology Internal Service Quality in a Manufacturing Environment encourages teamwork and team-oriented tasks. Where jobs require individual attention and scope, the company also assigns individual responsibilities and job tasks. However, all employees at Measuring Information Technology Internal Service Quality in a Manufacturing Environment are expected to be team players who can work well with and through other members, and who get along well with other people. The teams at Measuring Information Technology Internal Service Quality in a Manufacturing Environment are supportive of all embers and work in synch with synergy towards achieving the broader team objectives and goals under the Measuring Information Technology Internal Service Quality in a Manufacturing Environment designed strategy and values.

1.2.4. Centralization vs. decentralization

Measuring Information Technology Internal Service Quality in a Manufacturing Environment has a hybrid structure between centralization and decentralization. Like many progressive organizations, Measuring Information Technology Internal Service Quality in a Manufacturing Environment largely supports decentralized decision making. Job roles at Measuring Information Technology Internal Service Quality in a Manufacturing Environment are designed to be carried out with responsibility, and employees often set their goals with mutual coordination and understanding with the supervisors.

However, Measuring Information Technology Internal Service Quality in a Manufacturing Environment is also centralized in making sure that supervisors oversee, and approve of the various efforts, and tactics that employees choose to ensure that they are aligned with the organizational strategy ad values.

1.2.5. Communication

Measuring Information Technology Internal Service Quality in a Manufacturing Environment has a developed and intricate system for ensuring communication between employees, and different managerial levels. The communication systems at Measuring Information Technology Internal Service Quality in a Manufacturing Environment enhance the overall organizational structure. The systematic, defined, and organized communication allows an easy flow of information and ensures that no organizational tasks and goals are compromised because of a lack of communication, or misunderstandings.

1.3. Systems

1.3.1. Organizational systems in place

Measuring Information Technology Internal Service Quality in a Manufacturing Environment has defined and well-demarcated systems in place to ensure that the business operations are managed effectively and that there are no conflicts or disputes. The systems at Measuring Information Technology Internal Service Quality in a Manufacturing Environment are largely departmental in nature, and include, for example:

- Human resource management

- Finance

- Marketing

- Operations

- Sales

- Supply chain management

- Public Relation Management

- Strategic leadership

1.3.2. Defined controls for systems

Each of the defined and demarcated systems at Measuring Information Technology Internal Service Quality in a Manufacturing Environment has especially designed tools and methods as controls for evaluating performance and goal attainment. These controls and measures are designed specifically in different departments based on the nature of their tasks and responsibilities. Moreover, each department also designs specific controls for members for performance evaluation, as well as for inter-departmental tasks and responsibilities.

1.3.3. Monitoring and evaluating controls

Measuring Information Technology Internal Service Quality in a Manufacturing Environment continually evaluates its systems through the designed controls. This monitoring of the performance is continual and ongoing. This is largely done through observation and informal discussions. Feedback to employees and overall department heads is informally given regularly as and when is required. Formal evaluation of performance is also conducted semiannually – or quarterly, depending on the need and the urgency of the projects and assigned tasks. This is a formal process that is undertaken by supervisors and managers to ensure the identification of performance lags, and suggestive means of improvement.

1.3.4. Internal processes for organizational alignment

Measuring Information Technology Internal Service Quality in a Manufacturing Environment also has special processes and methods for ensuring that all departments and systems within the organization are aligned and working in harmony towards the greater business goals and targets. This is made possible through ensuring that all systems are designing and working towards goals and targets specific to their expertise under the broader business vision and strategy. Moreover, the strategic leadership at Measuring Information Technology Internal Service Quality in a Manufacturing Environment also ensures that all systems are allocated with resources, and set specific targets to achieve similar business goals in any specific period.

2. Soft elements

The soft elements of the McKinsey 7s model, in turn, include shared values, staff, skills, and strategy. These elements are less tangible in nature and are more influenced by the organizational culture. As such, the management does not have direct influence or control over them. These elements are also harder to describe and directly identify – but are equally important for an organization’s success and improved performance.

2.1. Shared values

2.1.1. Core values

The core values at Measuring Information Technology Internal Service Quality in a Manufacturing Environment are defined and communicated to foster a creative and supportive organizational structure that will allow employees to perform optimally, and enhance their motivation and organizational commitment. The core values at Measuring Information Technology Internal Service Quality in a Manufacturing Environment include, but are not limited to:

- Creativity

- Honesty

- Transparency

- Accountability

- Trust

- Quality

- Heritage

The Measuring Information Technology Internal Service Quality in a Manufacturing Environment business also ensures that all its activities and operations are conducted with high ethical and moral standards that redefined and benchmarked against international criteria.

2.1.2. Corporate culture

Measuring Information Technology Internal Service Quality in a Manufacturing Environment encourages an inclusive culture that celebrates diversity. The company has an international presence, and production units that are spread across different countries, as such, Measuring Information Technology Internal Service Quality in a Manufacturing Environment ensure that its organizational culture is supportive of diversity, and has internal policies to reduce incidences of discrimination.

The corporate culture at Measuring Information Technology Internal Service Quality in a Manufacturing Environment also encourages innovation and creativity by allowing independence for growth to individuals and teams –thus helping them refine their careers as well as personalities. Lastly, the corporate culture at Measuring Information Technology Internal Service Quality in a Manufacturing Environment also has a supportive leadership which works towards increasing employee motivation and job satisfaction by giving way to visibility and accessibility.

2.1.3. Task alignment with values

Measuring Information Technology Internal Service Quality in a Manufacturing Environment ensures that all its job tasks and roles are aligned with the core values that the company propagates. This means that all activities, tactics, and strategic tactics employed by Measuring Information Technology Internal Service Quality in a Manufacturing Environment will reflect its core values, and will not deviate away from these. This is to ensure a consistent, and reliable brand image, as well as an honest organizational culture. In the event of organizational change, the company will continue to ensure that all change management processes and methods incorporate the core values so that the organizational culture is consistently maintained, and systematically changed if need be.

2.2. Style

2.2.1. Management/leadership style

Measuring Information Technology Internal Service Quality in a Manufacturing Environment has a participative leadership style. Through a participative leadership style, Measuring Information Technology Internal Service Quality in a Manufacturing Environment is able to engage and involve its employees in decision-making processes and managerial decisions. This also allows the leadership to regularly interact with the employees and different managerial groups to identify any potential conflicts for resolution, as well as for feedback regarding strategic tactics and operations. Through its participative leadership, Measuring Information Technology Internal Service Quality in a Manufacturing Environment is able to enhance employee motivation, and increase organizational commitment and ownership amongst employees as well as other stakeholders.

2.2.2. Effectiveness of leadership style

The participative leadership style is highly effective in achieving the business goals and vision of the organization. Employees feel to be active members of the organization who are valued for their suggestions, feedback, and input. Moreover, through participative leadership, leaders and managers are able to identify current and potential conflicts within the Measuring Information Technology Internal Service Quality in a Manufacturing Environment organization, and actively work to resolve them as soon as possible.

2.2.3. Cooperation vs competition – internally

With its supportive and encouraging organizational culture, Measuring Information Technology Internal Service Quality in a Manufacturing Environment gives way to internal collaboration and cooperation between employees, systems, teams, and departments. This cooperation and collaboration at Measuring Information Technology Internal Service Quality in a Manufacturing Environment is important since its operations are spread globally, and also because tasks and responsibilities within the company often require inter-departmental feedback and input. Moreover, with increased expansion, and synergy, the business also regularly forms project teams – which function effectively because of the cooperative and collaborative culture within the Measuring Information Technology Internal Service Quality in a Manufacturing Environment organization.

2.2.4. Team vs groups

Measuring Information Technology Internal Service Quality in a Manufacturing Environment has effective and functional teams and works with them internally to achieve its various business goals and objectives, and complete tasks. The company’s management is encouraging and supportive, and the leadership provides a motivating and pragmatic vision toad achieve. The human resource management system, as well as the organizational training, supports all employees in their growth fairly and transparently. This leads to effective team formation instead of nominal groups within the organization for various projects, as well as department-specific tasks and roles.

2.3. Staff

2.3.1. Employee skill level vs business goals

Measuring Information Technology Internal Service Quality in a Manufacturing Environment has a sufficient number of employees employed across its global operations. Employees for different job roles and positions are hired internally as well as externally – depending on the urgency and the skill levels required. Based on this, it is seen that Measuring Information Technology Internal Service Quality in a Manufacturing Environment has employees who are skilled as per the requirements of their job roles and positions. All employees are given in house training to familiarize themselves with the company and its values. External training along with in-house training is provided for skill level enhancement.

All job roles and positions are designed to facilitate the achievement of business goals, and as such, employee skill level at Measuring Information Technology Internal Service Quality in a Manufacturing Environment is sufficient to achieve the business goals of the company.

2.3.2. Number of employees

Measuring Information Technology Internal Service Quality in a Manufacturing Environment has employed a large number of employees. The number of employees varies from country to country as per the requirements and needs of the business and operations. The global team of Measuring Information Technology Internal Service Quality in a Manufacturing Environment is an inclusive one that accepts, and encourages diversity, and works in synchronization with members to ensure attainment of business goals. The team member sand employees are the most important part of business success for Measuring Information Technology Internal Service Quality in a Manufacturing Environment.

2.3.3. Gaps in required capabilities and capacities

Measuring Information Technology Internal Service Quality in a Manufacturing Environment has a well-defined system for identifying potential needs of capabilities and capacities for the organization. The human resource function of the business has a systematic process that aligns all other departments to identify potential vacancies or skill gaps. Based on the nature of the need, the human resource department arranges for recruitments which may be permanent or contractual in nature, as well as arranges training sessions if need be for the current workforce.

2.4. Skills

2.4.1. Employee skills

Measuring Information Technology Internal Service Quality in a Manufacturing Environment has a commendable workforce, with high skills and capacities. All employees are recruited based on their merit and qualifications. Measuring Information Technology Internal Service Quality in a Manufacturing Environment prides itself on hiring the best professionals and grooming them further to facilitate growth and development.

2.4.2. Employee skills vs task requirements

Measuring Information Technology Internal Service Quality in a Manufacturing Environment has defined tasks and job roles and hires and trains employees for skill levels accordingly with respect to those. The company ensures that all its job requirements are met and that employees have the sufficient skills to perform their respective jobs in accordance with the values and culture as well as the business goals and strategy of Measuring Information Technology Internal Service Quality in a Manufacturing Environment.

2.4.3. Skill management

Measuring Information Technology Internal Service Quality in a Manufacturing Environment pays particular attention to enhancing the skills and capacities of its employees. It arranges regular training and workshops – internally as well as externally managed- to provide growth and development opportunities for its employees. Measuring Information Technology Internal Service Quality in a Manufacturing Environment focuses on personal as well as professional growth for its employees and works accordingly with them.

2.4.4. Company’s competitive advantage

The human resource is one of the core competitive advantages of the company. The skills of employees are developed specifically for job roles and requirements at Measuring Information Technology Internal Service Quality in a Manufacturing Environment and provide a competitive benefit to the company – where players cannot imitate employee skills or training. This creates a unique and non-substitutable competency for Measuring Information Technology Internal Service Quality in a Manufacturing Environment.

3. References

Alam, P.A., 2017. Measuring Organizational Effectiveness through the Performance Management System and Mckinsey's 7 S Model. Asian Journal of Management, 8(4), pp.1280-1286.

Allaoui, S., Bourgault, M. and Pellerin, R., 2019. Business transformation frameworks: Comparison and industrial adaptation. Journal of Enterprise Transformation, pp.1-28.

Arvand, N. and Baroto, M.B., 2016. How to implement strategy more effectively. International Journal of Business Performance Management, 17(3), pp.301-320.

Baishya, B., 2015. McKinsey 7s Framework in corporate planning and policy. International Journal of Interdisciplinary Research in Science Society and Culture (IJIRSSC), 1(1), pp.165-168.

Channon, D.F. and Caldart, A.A., 2015. McKinsey 7S model. Wiley encyclopedia of management, pp.1-1.

Cordell, A. and Thompson, I., 2019. The Procurement Models Handbook. Routledge.

Daft, R., 2016. Contemporary Strategy Analyses. New York: John Wiley & Sons.

Doumi, K., Baina, S. and Baina, K., 2013. STRATEGIC BUSINESS AND IT ALIGNMENT: REPRESENTATION AND EVALUATION. Journal of Theoretical & Applied Information Technology, 47(1).

Galli, B.J., 2018. Change management models: A comparative analysis and concerns. IEEE Engineering Management Review, 46(3), pp.124-132.

Gökdeniz, İ., Kartal, C. and Kömürcü, K., 2017. Strategic assessment based on 7S McKinsey model for a business by using analytic network process (ANP). International Journal of Academic Research in Business and Social Sciences, 7(6), pp.2222-6990.

Grant, R., 2010. Contemporary Strategy Analysis and Cases: Text and Cases. Hoboken: NJ: ohn Wiley & Sons.

Hossain, A., 2019. Strategy implementation: Identification of explanatory variables for successful business analytics implementation in organizations.

Hrebiniak, L., 2005. Making strategy work. Philadelphia, PA: Wharton School Publishing.

Johnson, G., 2016. Exploring strategy: text and cases. Pearson Education.

Král, P. and Králová, V., 2016. Approaches to changing organizational structure: The effect of drivers and communication. Journal of Business Research, 69(11), pp.5169-5174.

Puranam, P. and Vanneste, B., 2016. Corporate strategy: Tools for analysis and decision-making. Cambridge University Press.

Ravanfar, M.M., 2015. Analyzing Organizational Structure based on the 7s model of McKinsey. Global Journal of Management And Business Research.

Shaqrah, A.A., 2018. Analyzing business intelligence systems based on 7S model of McKinsey. International Journal of Business Intelligence Research (IJBIR), 9(1), pp.53-63.

Singh, A., 2013. A study of role of McKinsey's 7S framework in achieving organizational excellence. Organization Development Journal, 31(3), p.39.

Singh, R., 2018. Developing Competitive Strength: Biggest Challenge for the Organizations. Managing Editor, p.65.

Zincir, O. and Tunç, A.Ö., 2017. An Imagination of Organizations in the Future: Rethinking McKinsey's 7S Model. In Strategic Imperatives and Core Competencies in the Era of Robotics and Artificial Intelligence (pp. 101-125). IGI Global.

4. Appendix

| Hard elements |

|

||||||||

| Soft elements |

|

Table 1McKinsey 7S model - summary

Warning! This article is only an example and cannot be used for research or reference purposes. If you need help with something similar, please submit your details here.

Related Articles

- Corporate Social Responsibility of Measuring Information Technology Internal Service Quality in a Manufacturing Environment

- Measuring Information Technology Internal Service Quality in a Manufacturing Environment 5C Marketing Analysis

- The vision statement of Measuring Information Technology Internal Service Quality in a Manufacturing Environment

- Organizational Culture of Measuring Information Technology Internal Service Quality in a Manufacturing Environment

- Measuring Information Technology Internal Service Quality in a Manufacturing Environment Generic and Intensive Growth Strategies

- Measuring Information Technology Internal Service Quality in a Manufacturing Environment Case Study Analysis & Solution

- Measuring Information Technology Internal Service Quality in a Manufacturing Environment Case Solution

- Ansoff Matrix of Measuring Information Technology Internal Service Quality in a Manufacturing Environment

- Blue Ocean Strategy of Measuring Information Technology Internal Service Quality in a Manufacturing Environment

- Hofstede Cultural Model of Measuring Information Technology Internal Service Quality in a Manufacturing Environment

- Porters Diamond Model of Measuring Information Technology Internal Service Quality in a Manufacturing Environment

- Resource Based View Of The Firm - Measuring Information Technology Internal Service Quality in a Manufacturing Environment

- VRIN/VRIO Analysis Of Measuring Information Technology Internal Service Quality in a Manufacturing Environment

- Net Present Value (NPV) Analysis of Measuring Information Technology Internal Service Quality in a Manufacturing Environment

- WACC for Measuring Information Technology Internal Service Quality in a Manufacturing Environment

Nelson Zeo

5.0

I got above 80% marks. I'll absolutely refer this service to all my friends. Thanks!

Drishti Ivaan

5.0

I never suffered as much as in my university life as I faced the situation when the professor of Management didn't agree to give us any relief. I picked up the assignment from this service and got the teacher to be satisfied with my performance. Thanks a lot!

Eric Zuhair

5.0

The assignment turned to me in a fabulous way and grades couldn't be better without this service.

Hugo Kieran

5.0

Fast and friendly customer service! The writer responded very quickly when I asked him a question. Great people!

Lina Luka

5.0

Every time, I give five stars to this service because it never gets me in problem regarding the delivery of the paper. Thanks a lot!

Fabio Leroy

5.0

It's very easy to work with this service because the experts do everything by himself and don't let students be worried.

Next Articles

- 47544-Predicting-Information-Technology-Adoption-in-Small-Businesses-An-Extension-of-the-Technology-Acceptance-Model-Mckinsey-7s

- 47545-Testing-a-Moderator-type-Research-Model-on-the-Use-of-High-Speed-Internet-Mckinsey-7s

- 47546-A-Binomially-Distributed-Production-Process-Revisited-A-Pedagogical-Approach-Mckinsey-7s

- 47547-Competition-in-Multi-channel-Supply-Chains-Mckinsey-7s

- 47548-Open-Innovation-Modeling-Using-Game-Theory-Mckinsey-7s

- 47549-Information-Security-Activities-of-College-Students-An-Exploratory-Study-Mckinsey-7s

- 47550-Managing-Risk-in-Operations-Mckinsey-7s

- 47551-Comparison-Study-on-Neural-Network-and-Ordinary-Least-Squares-Model-to-Stocks-Prices-Forecasting-Mckinsey-7s

- 47552-Satisfaction-and-Repurchase-Intention-B2B-Buyer-seller-Relationships-in-Medium-technology-Industries-Mckinsey-7s

- 47553-Lexicographic-Goal-Programming-Approaches-to-the-Three-group-Classification-Problem-Mckinsey-7s

Previous Articles

- 1-Making-the-Case-Mckinsey-7s

- 2-Joe-Smith-s-Closing-Analysis-B-Mckinsey-7s

- 3-Joe-Smith-s-Closing-Analysis-A-Spanish-Version-Mckinsey-7s

- 4-GMAC-The-Pipeline-Mckinsey-7s

- 5-On-Writing-Teaching-Notes-Well-Mckinsey-7s

- 6-Exxon-Corp-Trouble-at-Valdez-Mckinsey-7s

- 7-Ashland-Oil-Inc-Trouble-at-Floreffe-A-Mckinsey-7s

- 8-Ashland-Oil-Inc-Trouble-at-Floreffe-B-Mckinsey-7s

- 9-Ashland-Oil-Inc-Trouble-at-Floreffe-C-Mckinsey-7s

- 10-Ashland-Oil-Inc-Trouble-at-Floreffe-D-Mckinsey-7s

Be a Great Writer or Hire a Greater One!

Academic writing has no room for errors and mistakes. If you have BIG dreams to score BIG, think out of the box and hire Essay48 with BIG enough reputation.

Our Guarantees

Interesting Fact

Most recent surveys suggest that around 76 % students try professional academic writing services at least once in their lifetime!